Infrastructure

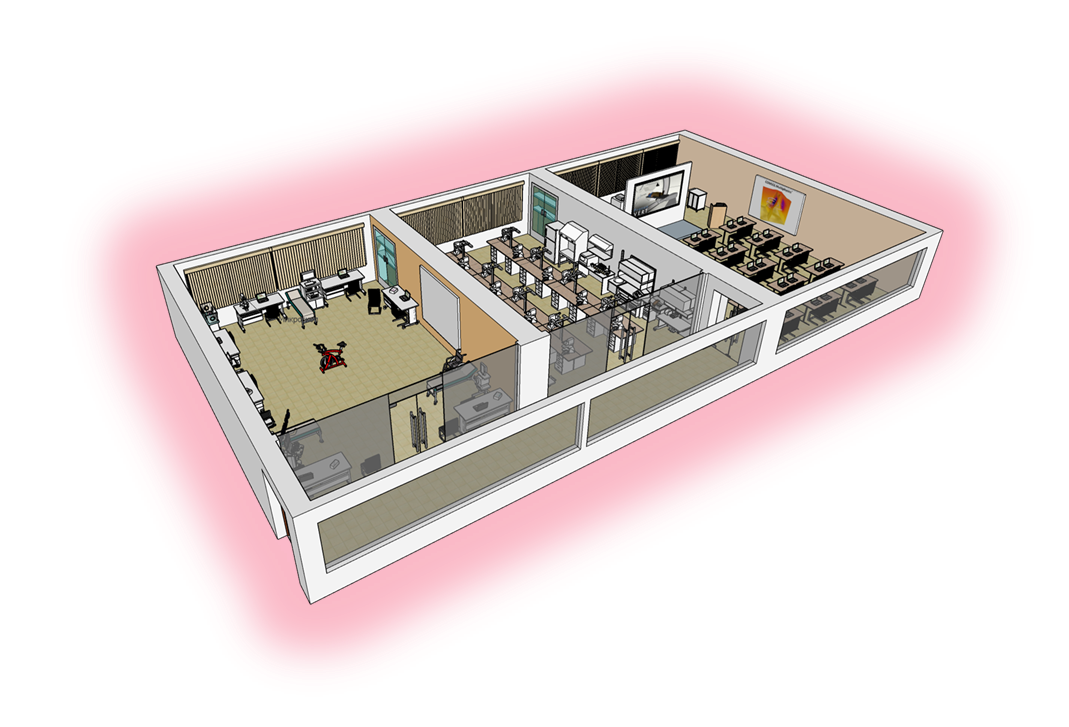

The center is designed to prepare students for work at modern digital robotic manufacturing plants and to teach them to design such facilities. It has four laboratories:

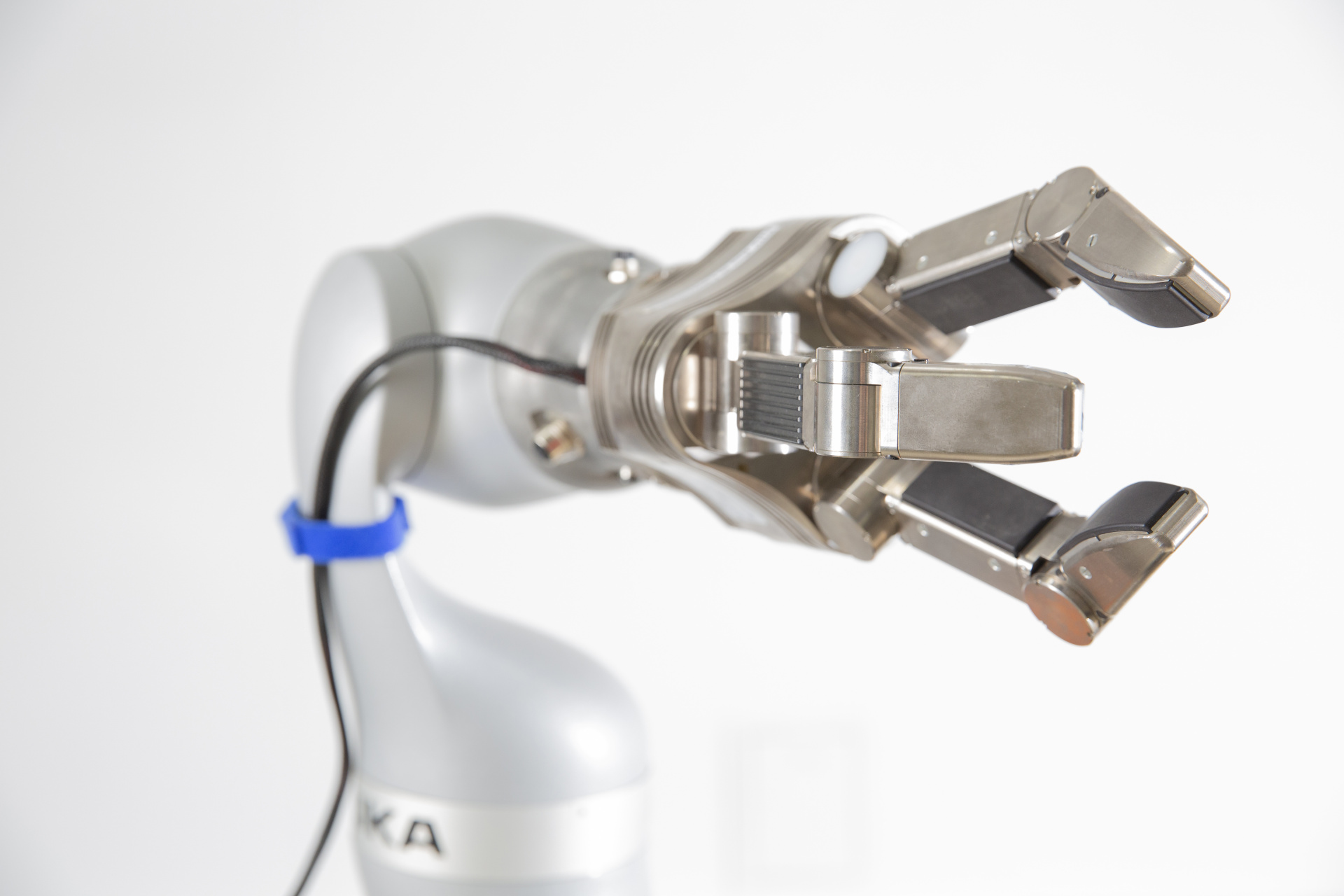

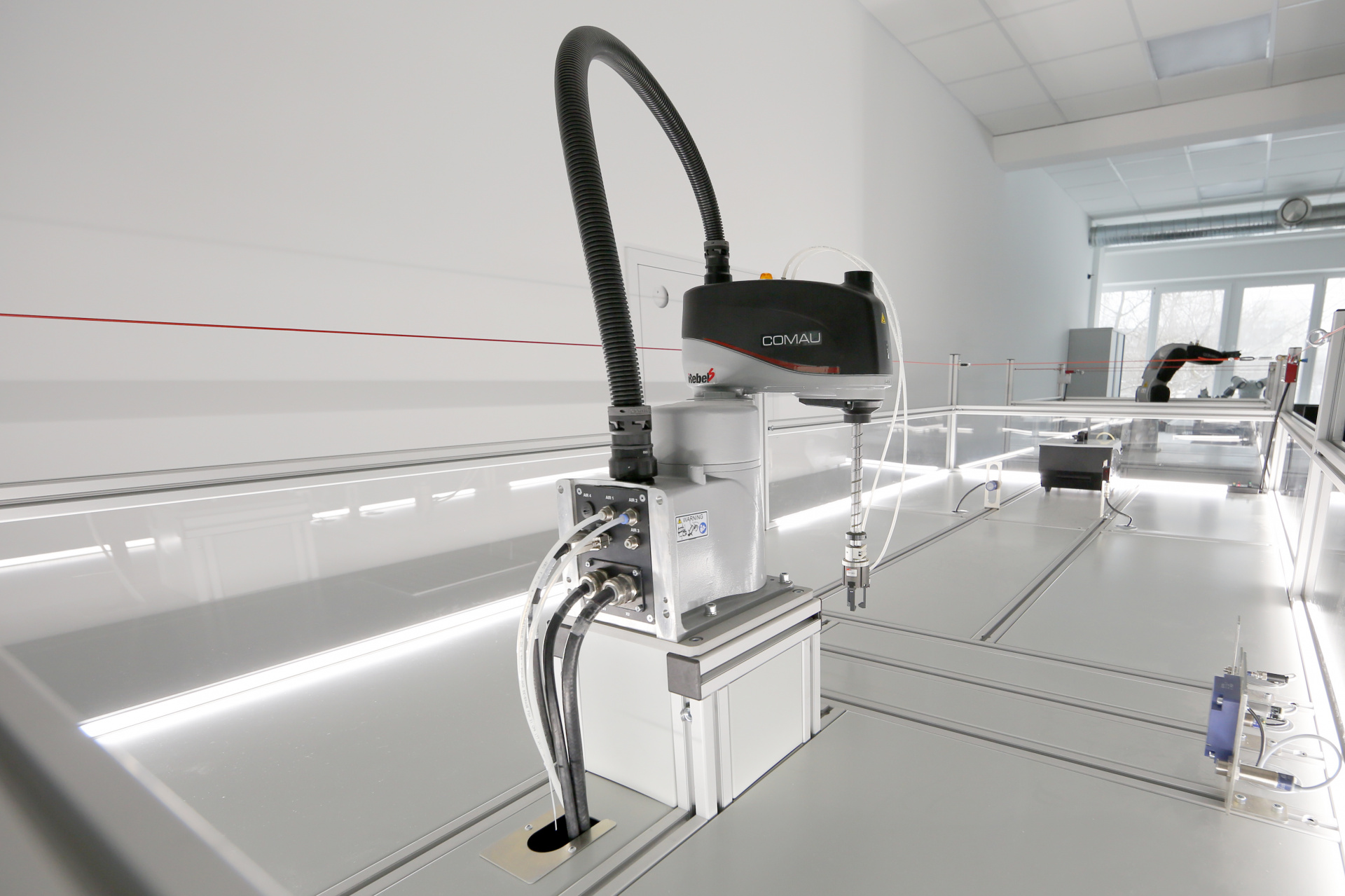

The Digital Robotics Manufacturing Laboratory is designed to train students in the design and programming of operations at robotic manufacturing facilities and the use of modern computer-aided design (CAD) tools for numerically controlled machines (CNC) as engineer or operator of contemporary SCADA systems and distributed process control systems in digital robotic manufacturing. The laboratory equipment includes 8 industrial robots connected by a common transport system, 2 robotic warehouses and 4 CNC machines.

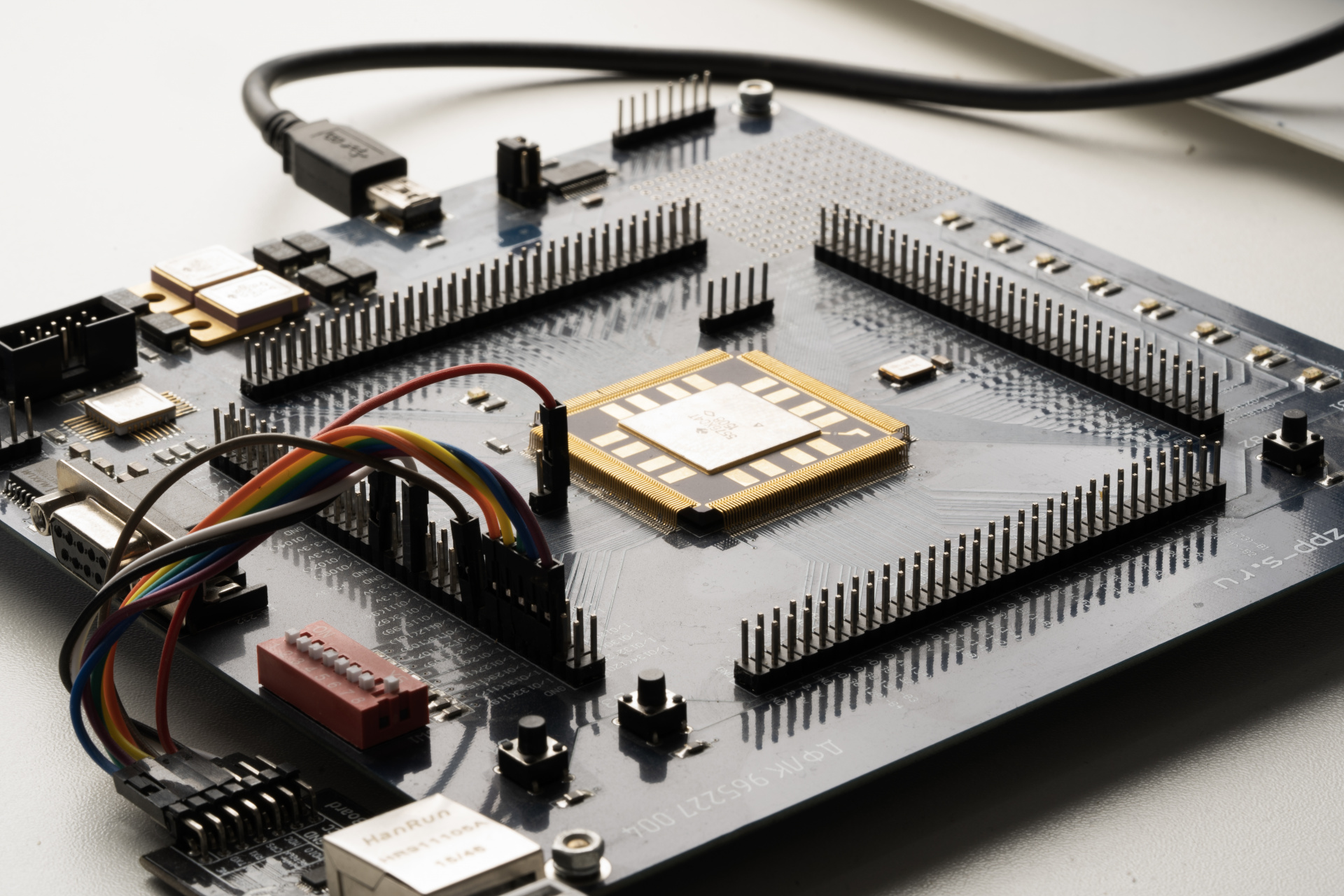

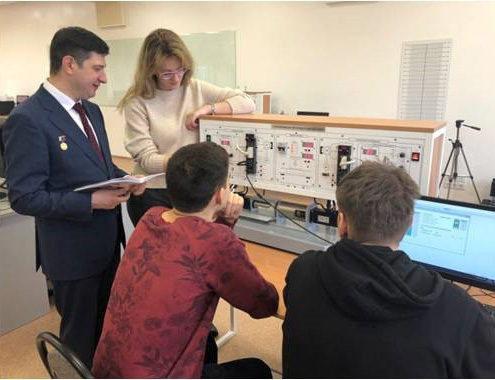

The Hardware Components for Industrial Robotics Control Systems Laboratory. At this laboratory, students learn to design control systems made up of modern industry-standard hardware components. Students also master advanced software development techniques for such systems, including the use of real-time operating systems and Hardware-In-Loop simulation. The equipment consists of eight workbenches, each equipped with a programmable logic controller (PLC), a frequency converter, a two-axis servo drive, two step drives, an emergency safety system conforming to IEC61508, a distributed I/O system, and a Cartesian kinematics training robot.

The Laboratory of Data Measuring Instruments for Industrial Robotic Systems. At this laboratory, students explore the reasonable choice method and learn to use modern data measuring instruments in designing industrial control systems, as well as to configure them in practice. The laboratory equipment includes vision systems, force-torque sensing systems, platform-free inertial navigation systems, ultrasonic and laser distance sensors.

The Laboratory of Mathematical Simulation and Digital Industrial Robot Twins is intended for students to acquire the skills of independent industrial control system design and to simulate and create digital twins of robot-based complexes.

All of the center’s equipment, including its robots, machine tools, transport system, air treatment station, ventilation and air conditioning systems, access control system, lighting and power supply, are controlled by a DCS APROL distributed process control system.

- Educational Activity

-

Institutes

- Institute of Information Technologies

-

Institute of Artificial Intelligence

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

- Bachelor's Degree Programs

-

Master's Degree Programs

- 01.04.02 Applied mathematics and information science

- 09.04.01. Informatics and computer engineering

- 12.04.04 Biotechnical systems and technologies

- 15.04.04 Automation of technological processes and production

- 15.04.06 Mechatronics and robotics

- 27.04.03 System analysis and management

- 27.04.04 Engineering system control

- Infrastructure

- Alumni

- Contacts

- Institute for Cybersecurity and Digital Technologies

-

Institute for Advanced Technologies and Industrial Programming

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

-

Bachelor's Degree Programs

- 09.03.02 Information systems and technologies

- 11.03.04 Electronics and nanoelectronics

- 12.03.05 Laser technology and laser techniques

- 15.03.01 Mechanical engineering

- 22.03.01 Materials science and technology

- 27.03.01 Standardization and metrology

- 28.03.01 Nanotechnology and microsystems engineering

- 29.03.04 Decorative material working techniques

- 54.03.01 Graphic design

-

Master's Degree Programs

- 09.04.02. Information systems and technologies

- 11.04.04 Electronics and nanoelectronics

- 12.04.02 Optical engineering

- 15.04.01 Mechanical engineering

- 22.04.01 Materials science and technology

- 27.04.01 Standardization and metrology

- 29.04.04 Decorative material working techniques

- 54.04.01 Graphic design

-

Bachelor's Degree Programs

- Infrastructure

- Alumni

- Contacts

- Institute of Radio Electronics and Informatics

- Institute of Management Technologies

- Lomonosov Institute of Fine Chemical Technologies

- Institute of International Education

-

Mega-Laboratories

- Motion Capture Laboratory

- Immersive Technologies Laboratory

- Laboratory for the Development and Transfer of Microfluidic Technologies (DTMT)

- Cell Technologies Megalaboratory operating on the basis of the Department of Chemistry and Technology of Biologically Active Compounds, Medical and Organic Chemistry named after N.A. Preobrazhensky

- General Biotechnology Megalaboratory

- Industry 4.0: Digital Robotized Production center

- Laboratory of Intelligent Autonomous and Multi-Agent Robotic Systems

- Research and Educational Center for Biosynthesis, Isolation and Purification of Monoclonal Antibodies (Generium)

- Rare and Precious Metals Research and Technological Center operating on the basis of the Department of Chemistry and Technology of Rare Elements named after K.A. Bolshakov

- Laboratory of Analytic, Modeling, Design and Digital Prototyping Technologies

- Import Substitution of Information Technologies Educational and scientific testing complex

- Smart Production Systems Educational and Scientific Center

- Elastomers. Thermoplastics. Technologies Educational and Research Center operating on the basis of the Department of Chemistry and Technology of Elastomer Processing named after F.F. Koshelev

- Catalytic and Mass Exchange Processes center

- Center of Innovative Technologies in Microelectronics

- Center for Cybersports Robotics

- Mobile Robotics University Laboratory

- Radio electronic Technologies Megalaboratory

- Departmental Situation Center of the Ministry of Science and Higher Education of the Russian Federation for monitoring the sphere of education and science

- Scientific and Educational Center for Medical Radiology and Dosimetry

- Laboratory of Geographic Information Systems and Technologies

- Educational and Research Center for Space Monitoring ("CosMoCenter")

- Additive Polymer Technologies Center

- Cyber Threat Research Megalaboratory

- Digital Center of Rosatom State Corporation

- Laser Technologies Megalaboratory

- Mathematical Modeling and Artificial Intelligence Megalaboratory

- Megalaboratory of Digital and Additive Technologies in Mechanical Engineering

- Nanomaterials and Nanostructures Diagnostics Center

- Techno-coworking

- TESLA Educational and Research Center

- Bachelor's Degree Programs

- Master's Degree Programs

- Additional Education Programs

- Physical Education and Sports

© 2026 MIREA - Russian Technological University