Infrastructure

It is important for future chemists to have the knowledge and skills that will allow them to work both in science and in real production. For the purpose, Lomonosov Institute of Fine Chemical Technologies has created conditions for practical activity of students and for the implementation of student projects. Over 30 laboratories with all the necessary equipment have been opened on the premises of the Institute.

The educational process at Lomonosov Institute of Fine Chemical Technologies is conducted in classrooms, laboratories and computer labs equipped with modern facilities.

Lecture room K-3 on the campus premises at Vernadsky Avenue, 86

Historical lecture room A-63 on the campus premises on Malaya Pirogovskaya, 1

Historical lecture room A-63 on the campus premises on Malaya Pirogovskaya, 1

Historical lecture hall A-61 on the campus premises on Malaya Pirogovskaya, 1

Computer room K-209 on the campus premises at Vernadsky Avenue, 86

It is especially important for future specialists to have fundamental knowledge and practical skills of working with modern equipment, which will enable them in future to find their vocation both in science and real sector production. For the purpose, the Institute has created all the necessary conditions for students to engage in laboratory work, take various internships, and to implement student projects. On the premises of 22 departments of the Institute, more than 90 laboratories have been opened. All of them are equipped with all the necessary instruments and devices.

The new Research and Educational Center for biosynthesis, isolation and purification of monoclonal antibodies started operating at the Department of Biotechnology and Industrial Pharmacy to train highly qualified personnel for the biopharmaceutical industry. The development and production of a new generation of immunobiological preparations based on monoclonal antibodies is currently one of the most progressive areas of biopharmaceuticals. The laboratory equipped with modern instruments and devices for modeling the processes of production and purification of monoclonal antibodies will provide an effective selection and targeted training of specialists with profound knowledge of theory and practical skills allowing them to solve existing problems in the real sector.

Research and educational center for biosynthesis, isolation and purification of monoclonal antibodies

Generium MABstudY laboratory

On the basis of the departments of physical chemistry, general chemical technology, chemistry and technology of basic organic synthesis which have accumulated an extensive expertise in training and research in the field of catalytic processes and systems, energy-efficient processes for the separation of reaction mixtures, the Institute created an Interdepartmental Educational and Research Center for Catalytic and Mass Transfer Processes.

The center has created all the conditions for improving the quality of academic and practical training of students and graduate students who can acquire new engineering competencies and research skills. The center resources and facilities are in high demand when educational programs for bachelor’s and master’s degrees in the areas of Chemistry and Chemical technology are under way.

During the training process, the students get familiarized with their potential jobs and receive practical skills in working with modern analytical instruments: gas chromatographs, gas chromatography-mass spectrometers for various purposes; universal flow-circulation plants equipped with the necessary devices for testing and studying catalysts in a wide range of temperatures and pressures.

The center is equipped with stands for experimental study of mass transfer processes (rectification, liquid extraction, absorption).

Educational and Research Center for Catalytic and Mass Transfer Processes.

Gas-liquid chromatograph

Educational and Research Center for Catalytic and Mass Transfer Processes.

General form. Catalytic unit (on the left), absorption stand (in the center), rectification stand (on the right)

Educational and Research Center for Catalytic and Mass Transfer Processes.

Liquid-liquid extraction stand (in the center). Stand "Rectification" (on the left)

Educational and Research Center for Catalytic and Mass Transfer Processes.

"Absorption" Stand

Microfluidic Technologies Laboratory

In the laboratory for the synthesis and isolation of biologically active substances it is possible to solve a number of tasks, such as the synthesis of biologically active substances, the production of polymer nano- and microparticles.

The laboratory of sterile dosage forms of the Department is equipped with modern Swiss technological instruments and devices and serves not only as a demonstration platform for students, but also is of academic and educational purpose. This is the place where students get practical training on the development of sterile dosage forms. The sterility of the room is achieved through special ventilation equipment, disinfection and a sluice system.

Laboratory of sterile dosage forms

Laboratory of sterile dosage forms. Blister machine

Laboratory for the development of solid dosage forms

Film coating laboratory

Chromatographic laboratory

Titration-based methods of analysis. Students learn techniques of solution preparation, sampling, titration, statistical processing of analysis results and interpretation of results when conducting quantitative analysis of substances by titration-based methods. This will allow to further solve practical goals and objectives when analyzing various substances and materials in accordance with the methods named below.

Electrochemical analysis methods. Students learn the quantitative analysis of substances by coulometry, potentiometry, polarography, stripping voltammetry. On the basis of recent achievements students can also study the ion transfer across microscopic phase boundaries and ways to apply this knowledge in analytical chemistry.

Spectral analysis methods. Students learn the quantitative analysis of substances by spectrophotometry and luminescence analysis, analyze various molecular forms, including multicomponent mixtures of substances.

Mass spectrometry. Future professionals study the techniques and methods of mass spectral analysis, learn the principles and techniques for decoding mass spectra of inorganic and organic compounds, as well as the process of preparing the substance for analysis.

X-ray photoelectron spectroscopy. Those who study at the Institute can learn how to qualitatively and quantitatively determine the composition of matter by X-ray photoelectron spectroscopy. They will also learn how to determine the valence states of the elements that make up the analyzed sample, decode XPS data, analyze nanoparticles and nanomaterials, including polymer composite materials.

Chromatographic methods. Students study methods of chromatographic separation of substances, preparative chromatography, methods of sampling and sample preparation of substances for chromatographic analysis, and multicomponent systems analysis.

Chemical sensors. Students study methods of creating sensors based on metal complexes of porphyrins and phthalocyanines, methods of forming the gas sensitive element of the sensor, and study how to measure the sensors sensitivity to ammonia and nitrogen oxides of chemical and physicochemical processes (complexation, protolysis, etc.).

At the Department of Processes and Chemical Technology Equipment named after N.I. Gelperin, laboratory work is carried out with the use of the experimental identification of the most important characteristics associated with energy consumption during the flow of liquid and gas. The technical equipment of the department meets all the modern standards of industrial technologies and, due to that, provides training for bachelors and masters at a high professional level.

![]()

![]()

![]()

• study and compare the work of different types of pumps;

• calculate industrial pipelines with various valves and determine the parameters of the fluid flow in them;

• study the operation of a drying cabinet with infrared and convective heat supply;

• investigate the non-stationary thermal conductivity of materials;

• study the operation of a reversible heat pump;

• study heat transfer during the flow of liquid in a pipe and its cooling under conditions of natural and forced convection;

• study the heat technology of fluids and investigate heat transfer by radiation.

Laboratory of Photo Processes. The laboratory is developing organic photo matrices to obtain images in the visible and infrared spectral ranges.

Laboratory of Quantum Chemical Research. The laboratory is engaged in modeling chemical processes and establishing reaction mechanisms. Using the laboratory resources, students can complete their graduation papers and projects in theoretical modeling. Calculations are made with high-performance computers.

Laboratory of physical chemistry of liquid crystals. The laboratory conducts research in physical chemistry of liquid crystals and systems based thereon. Today the work is underway on modeling phase equilibria, calculating physical and thermodynamic properties of individual liquid crystals and industrial mixtures.

Laboratory of Chemical Kinetics and Catalytic Processes. The laboratory develops homogeneous and heterogeneous catalysts for a large number of important practical processes related to the production of fuels, monomers and intermediate products for organic synthesis, and for solving economic and energy issues.

At the Department of Chemistry and Technology of Biologically Active Compounds, Medical and Organic Chemistry named after N.A. Preobrazhensky, future specialists can acquire the skills of working in laboratories:

Technologies for the isolation and purification of biologically active compounds from natural raw materials. Students learn to isolate pigments, carotenoids, lipid components, etc. from biological sources.

Laboratory of physical-chemical and spectral methods of analysis of biologically active substances and pharmaceutical substances. Students master modern methods of analysis and purification of biologically active substances while applying high performance liquid chromatography, electronic spectroscopy, and determining the melting point of materials.

Laboratory for fine organic synthesis of pharmaceutical substances and finished dosage forms. Students acquire skills in obtaining innovative drugs, including targeted and membranotropic substances, and also develop nanotechnological means of their delivery (liposomes, nanoparticles of various nature).

The department has modern equipment for solving problems of bioorganic and medicinal chemistry, including spectrophotometers, rotary evaporators, high-performance liquid chromatographs.

Organic chemistry laboratory O-401 on the campus at Vernadsky Avenue, 86

Polymer synthesis technology. The laboratory is equipped with advanced technological instruments and devices for polymer synthesis. Students acquire skills in getting polymers used not only in industry and the national economy, but also in biotechnology, medicine, and nano-industry.

Methods to study polymers and polymer composites. Polymer synthesis technology is inconceivable without the symbiosis of synthesis and analysis. A modern specialist in polymer synthesis must know and must be able to apply a wide range of methods for studying polymers. It is in this laboratory that students acquire such knowledge and skills.

Laboratory of research methods for polymers and polymer composites

Particle size analyzer (particle size distribution) of suspensions and dry powders Malvern Mastersizer 2000

DSC 204 F1 Phoenix® Differential Scanning Heat Flux Calorimeter

At the Department of Chemistry and Technology of Basic Organic Synthesis, students and graduates can acquire knowledge and expertise in the following laboratories:

University laboratory of catalytic processes of basic organic synthesis. In the laboratory, students get to know methods for studying catalytic processes (reactions of dehydrogenation of alcohols, dehydration of alcohols, esterification). In the working process, students independently carry out the main stages of experimental research: prepare catalysts, determine the conditions for the chemical process on the basis of thermodynamic data, test catalysts, assess the optimal conditions for the process, evaluate the effect of the catalyst composition on the process indicators. The laboratory is equipped with installations and devices to carry out chemical processes and modern chromatographs that allow to monitor the work progress.

University laboratory for separation processes of mixtures of basic organic synthesis. In the laboratory, students acquire skills in experimental research of physical and chemical properties, phase equilibria of binary and multicomponent mixtures, rectification separation methods. Research is carried out with the use of ebulliometry methods (Svetoslavsky ebulliometers, modified ebulliometers), gas-liquid chromatography, refractometric methods. During internship, students get acquainted with the device and the principle of operation of an automated rectification column (metal rectification column 4 meters high).

Specialized research laboratories. In research laboratories, students performing qualification work are engaged in the development and improvement of catalysts, the study of mechanisms of catalytic reactions (reactions of acetylene carbonylation, oxidation of olefins, oxidation of carbon monoxide (II)). The study of these processes is accounted for by the need to create new technologies for receiving products of basic organic synthesis, the development of methods for the synthesis of isotope-containing medical diagnostic preparations, and the improvement of catalysts for respiratory protection. The laboratories are equipped with instruments and installations to study catalytic processes, spectral instruments (IR and UV spectrophotometers), chromatographs, gas analyzers, and instruments for determining air humidity.

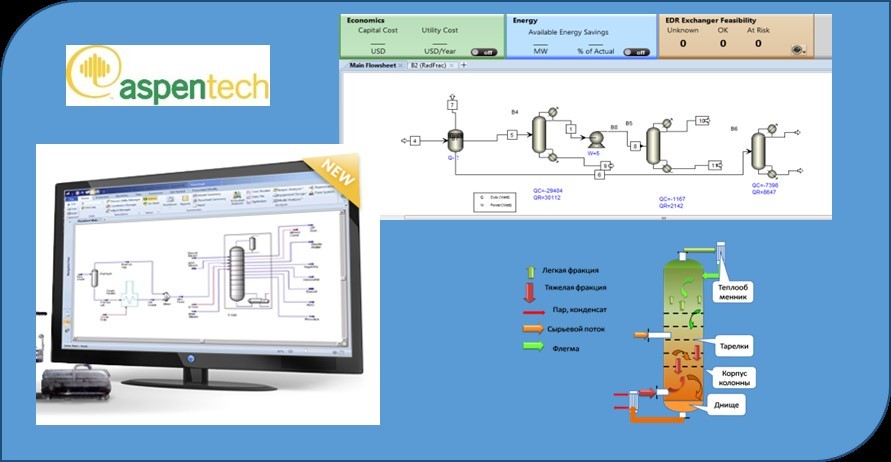

Computer class. The class is equipped with modern computer technology. Students have access to the licensed software package from Aspen Technology (AspenPlus®, AspenHysys®), a modern tool that allows to simulate the properties of systems, make calculations and optimize various chemical and technological processes. Students gain the skill to conduct computational experiments and make pre-design calculations in order to develop new or increase the efficiency of the already existing technologies for organic products.

Aspen Technology specialized software package

• technological laboratory;

• laboratory for structural studies, rheology, polymer composite materials and modern polymer binders, reinforced plastics (together with JSC NPO Stekloplastik). The laboratory is equipped with a set of instruments for assessing the fluidity and formability of polymer materials: Brookfield viscometers (Germany), a viscometer for determining the MFI of thermoplastics from Gottfert (Germany), a Dinisco capillary rheometer (USA);

• polymer nanofibers and materials joint laboratory (together with the department of HTPE);

• laboratory for research of physical and mechanical properties and laboratory for research of optical properties.

The Department is equipped with advanced instruments and devices, including:

• testing equipment for assessing the complex of technological, physical-mechanical and special properties of polymers and polymer composite materials. With the equipment described, it is possible to conduct thermal analysis of polymers and composite materials, study the structure of polymers and PCM, study the rheological properties of polymers, the structure of polymers using infrared spectroscopy method, determine the physical and mechanical properties of polymers and composite materials;

• modern devices and installations, including equipment for the production of thermoplastic polymer composite materials, films and injection molding on machines with software. Future industry professionals acquire practical skills in pressing materials and items, molding products by vacuum forming, processing thermoplastics by extrusion and injection molding. While using modern research equipment, students acquire the necessary skills and knowledge about the structure and properties of polymers and composite materials, and also get training in directional design;

Laboratory of the Department of Chemistry and Technology of Plastics and Polymer Composites Processing

Laboratory for manufacturing and testing adhesives and sealants. Future specialists study the fundamentals of adhesion – the science of gluing various materials, development of adhesives, sealants and adhesive tapes. The program course is headed by Professor L.R. Lyusova, a leading specialist, Vice-President of the Association of Adhesives and Sealants of Russia, Doctor of Technical Sciences.

Technological laboratory for manufacturing and vulcanization of rubber compounds. The laboratory includes industrial equipment for the rubber industry. It also has every possibility for the visual demonstration of the full production cycle of rubber technical products from tires and medical products to children's toys: balls, erasers, balloons, etc.

Electroforming of fibrous materials. Research of polymer solutions. Physical and chemical foundations for polymer processing via solution. Physical and chemical foundations for creating mixtures and polymer alloys. The head of the laboratory is one of the founders of the electrospinning technology, Doctor of Chemical Sciences, Professor Yu.N. Filatov.

The experience of working in unique laboratories can be obtained at the Department of Energy Technologies, Systems and Installations:

Laboratory of hydrogen energy. The laboratory is engaged in creating environmentally friendly and highly efficient power sources – the new generation fuel cells. With the help of special nanofilament electrodes developed at our department, the fuel energy is converted into electrical power bypassing the thermal stage. Such power sources are required as energy buffers in all renewable energy sources.

CAD laboratory. The laboratory is developing new generation materials providing efficient heat removal from electronic circuits based on nanocomposite materials. Apart from that, the laboratory deals with stealth materials, that is, materials that provide radio invisibility.

Moreover, the laboratory is engaged in design, creation and testing of modern microprocessor-based control and measuring equipment for environmental control and other types of chemical analysis.

- Educational Activity

-

Institutes

- Institute of Information Technologies

-

Institute of Artificial Intelligence

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

- Bachelor's Degree Programs

-

Master's Degree Programs

- 01.04.02 Applied mathematics and information science

- 09.04.01. Informatics and computer engineering

- 12.04.04 Biotechnical systems and technologies

- 15.04.04 Automation of technological processes and production

- 15.04.06 Mechatronics and robotics

- 27.04.03 System analysis and management

- 27.04.04 Engineering system control

- Infrastructure

- Alumni

- Contacts

- Institute of Radio Electronics and Informatics

-

Institute for Advanced Technologies and Industrial Programming

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

-

Bachelor's Degree Programs

- 09.03.02 Information systems and technologies

- 11.03.04 Electronics and nanoelectronics

- 12.03.05 Laser technology and laser techniques

- 15.03.01 Mechanical engineering

- 22.03.01 Materials science and technology

- 27.03.01 Standardization and metrology

- 28.03.01 Nanotechnology and microsystems engineering

- 29.03.04 Decorative material working techniques

- 54.03.01 Graphic design

-

Master's Degree Programs

- 09.04.02. Information systems and technologies

- 11.04.04 Electronics and nanoelectronics

- 12.04.02 Optical engineering

- 15.04.01 Mechanical engineering

- 22.04.01 Materials science and technology

- 27.04.01 Standardization and metrology

- 29.04.04 Decorative material working techniques

- 54.04.01 Graphic design

-

Bachelor's Degree Programs

- Infrastructure

- Alumni

- Contacts

- Institute for Cybersecurity and Digital Technologies

- Lomonosov Institute of Fine Chemical Technologies

- Institute of International Education

- Institute of Management Technologies

-

Mega-Laboratories

- Industry 4.0: Digital Robotized Production center

- Laboratory of Intelligent Autonomous and Multi-Agent Robotic Systems

- Laboratory of Analytic, Modeling, Design and Digital Prototyping Technologies

- Motion Capture Laboratory

- Center of Innovative Technologies in Microelectronics

- Catalytic and Mass Exchange Processes center

- Cell Technologies Megalaboratory operating on the basis of the Department of Chemistry and Technology of Biologically Active Compounds, Medical and Organic Chemistry named after N.A. Preobrazhensky

- Center for Cybersports Robotics

- Elastomers. Thermoplastics. Technologies Educational and Research Center operating on the basis of the Department of Chemistry and Technology of Elastomer Processing named after F.F. Koshelev

- Immersive Technologies Laboratory

- Import Substitution of Information Technologies Educational and scientific testing complex

- Laboratory for the Development and Transfer of Microfluidic Technologies (DTMT)

- Mobile Robotics University Laboratory

- Rare and Precious Metals Research and Technological Center operating on the basis of the Department of Chemistry and Technology of Rare Elements named after K.A. Bolshakov

- Research and Educational Center for Biosynthesis, Isolation and Purification of Monoclonal Antibodies (Generium)

- Smart Production Systems Educational and Scientific Center

- Techno-coworking

- Technocoworking

- Radio electronic Technologies Megalaboratory

- Situation center

- Scientific and Educational Center for Medical Radiology and Dosimetry

- Educational and Research Center for Space Monitoring ("CosMoCenter")

- Laboratory of Geographic Information Systems and Technologies

- Bachelor's Degree Programs

- Master's Degree Programs

- Additional Education Programs

- Physical Education and Sports

© 2024 MIREA - Russian Technological University