Infrastructure

The Institute is made up of 22 study laboratories, a specialized inter-university training and research laboratory named “Coherent Phase Microscopy” and a research and training center named “Magnetoelectric Materials and Devices.”

The laboratories of the general education departments give hands-on training to students in the framework of the General Practical Training Program in Physics. At the Physics Department, they do lab work in mechanics, molecular physics, electricity, magnetism, and optics; at the Electronics Department, their lab practice also enables them to study modern generators and oscilloscopes.

The laboratories of the general education departments give hands-on training to students in the framework of the General Practical Training Program in Physics. At the Physics Department, they do lab work in mechanics, molecular physics, electricity, magnetism, and optics; at the Electronics Department, their lab practice also enables them to study modern generators and oscilloscopes.

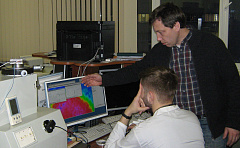

Specialized Inter-University Training and Research Laboratory of Coherent Phase Microscopy

This laboratory is where undergraduates and graduates develop:

- new techniques of analysing phase images that provide quantitative data on the morphology and functional state of a live cell;

- methods to assess the impact of various materials whose surface is modified with complex cluster-beam technology on the biological cell.

- new techniques of analysing phase images that provide quantitative data on the morphology and functional state of a live cell;

- methods to assess the impact of various materials whose surface is modified with complex cluster-beam technology on the biological cell.

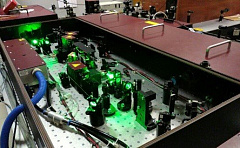

Nanotechnology Femtosecond Optics Laboratory

This laboratory is where students conduct research on the spectral, fluorescent and nonlinear optical characteristics of (nano)materials.

The spectral characteristics testing complex for materials consists of three components: a laser scanning confocal microscope, a high-luminosity spectrograph, and a photomultiplier tube.

The equipment can be used for independent research by graduate and master’s program students for their theses/projects. The experimental research automation software (also functional in the remote access mode) has been fully developed and implemented by our young researchers.

The Laboratory participates in joint projects with other organizations: Moscow Lomonosov State University (research and graduation projects); the United Institute of High Temperatures of the Russian Academy of Sciences, the Ioffe Physics and Technology Institute of RAS (a joint project under the auspices of the Russian Science Foundation).

The spectral characteristics testing complex for materials consists of three components: a laser scanning confocal microscope, a high-luminosity spectrograph, and a photomultiplier tube.

The equipment can be used for independent research by graduate and master’s program students for their theses/projects. The experimental research automation software (also functional in the remote access mode) has been fully developed and implemented by our young researchers.

The Laboratory participates in joint projects with other organizations: Moscow Lomonosov State University (research and graduation projects); the United Institute of High Temperatures of the Russian Academy of Sciences, the Ioffe Physics and Technology Institute of RAS (a joint project under the auspices of the Russian Science Foundation).

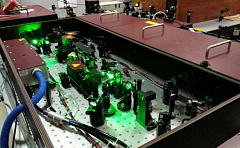

Superfast Ferroic Dynamics Laboratory

This laboratory carries out experimental and theoretical studies of fast-running processes in functional (nano)materials using the time resolution spectroscopy method, including the teracycle range, as part of the following training courses: Micro- and Nanosystem Diagnostics and Analysis Methods, Optical Nanostructure Diagnostics Methods, etc.

The testing facility for research on superfast ferroic dynamics consists of three main components: a femtosecond laser system, a single-pulse isolation system, and a single-pulse duration meter.

The Laboratory participates in joint projects with Radboud University Nijmegen (Netherlands), the Joint Institute of High Temperatures of the Russian Academy of Sciences, and the Moscow Institute of Physics and Technology.

The testing facility for research on superfast ferroic dynamics consists of three main components: a femtosecond laser system, a single-pulse isolation system, and a single-pulse duration meter.

The Laboratory participates in joint projects with Radboud University Nijmegen (Netherlands), the Joint Institute of High Temperatures of the Russian Academy of Sciences, and the Moscow Institute of Physics and Technology.

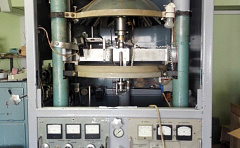

Specialized Research Laboratory of Magnetism and Magnetic Materials

The laboratory’s main experiment apparatus includes a Mössbauer spectrometer, a nuclear magnetic resonance spectrometer, a vibration magnetometer, and special and standard high-temperature furnaces for the synthesis and manufacture of magnetic material specimens.

In the laboratory, undergraduate and graduate students explore the physics of magnetic phenomena in substances, the types and properties of magnetic materials along with technologies for their production, and the local atomic, magnetic and electronic structures of amorphous, nanocluster and nanocrystalline substances.

Experimental research relies on the methods of nuclear physics using the Mössbauer and nuclear magnetic resonance spectrometers. It is centered around a local probe to investigate the magnetic and electronic properties as well as the local structure of magnetics, including nanoclusters and nanocrystals in the 0.5–1 nm range.

In the laboratory, undergraduate and graduate students explore the physics of magnetic phenomena in substances, the types and properties of magnetic materials along with technologies for their production, and the local atomic, magnetic and electronic structures of amorphous, nanocluster and nanocrystalline substances.

Experimental research relies on the methods of nuclear physics using the Mössbauer and nuclear magnetic resonance spectrometers. It is centered around a local probe to investigate the magnetic and electronic properties as well as the local structure of magnetics, including nanoclusters and nanocrystals in the 0.5–1 nm range.

Specialized Training and Research Laboratory of Microsystem Element Simulation and Design

The laboratory serves to train students computer simulation of physical processes, including those in microsystems and micro- and nanoelectronic device components.

Precision Materials Working Laboratory

At this laboratory, students pursuing bachelor’s, master’s and graduate programs explore and perform:

- cutting of a wide range of fragile non-metallic materials (sapphire, glass, quartz, ceramics, silicon, etc.) by laser-controlled thermal splitting (LUT);

- cutting by ultraviolet laser scribing;

- cutting of instrument plates into chips (fragments);

- cutting of round and square glass tubes;

- laser processing of glass;

- optical mesh application.

Russia’s first industrial installation MLP1-1060/355 for precision cutting of sapphire substrates and other fragile non-metallic materials.

- cutting of a wide range of fragile non-metallic materials (sapphire, glass, quartz, ceramics, silicon, etc.) by laser-controlled thermal splitting (LUT);

- cutting by ultraviolet laser scribing;

- cutting of instrument plates into chips (fragments);

- cutting of round and square glass tubes;

- laser processing of glass;

- optical mesh application.

Russia’s first industrial installation MLP1-1060/355 for precision cutting of sapphire substrates and other fragile non-metallic materials.

Special Polymer Composites Laboratory

At this laboratory, students pursuing bachelor’s, master’s and graduate programs explore and practice:

- production of special polymer composites with various granular fillers;

- production of thermally conductive polymer composites with a broad range of characteristics;

- production of electroconductive polymer composites with a broad range of characteristics;

- production of special polymer composites with various plate-shaped and thick-film fillers.

Extrusion equipment complex to manufacture special polymer composites.

- production of special polymer composites with various granular fillers;

- production of thermally conductive polymer composites with a broad range of characteristics;

- production of electroconductive polymer composites with a broad range of characteristics;

- production of special polymer composites with various plate-shaped and thick-film fillers.

Extrusion equipment complex to manufacture special polymer composites.

Probe Microscopy Laboratory

At this laboratory, students pursuing bachelor’s, master’s and graduate programs study:

- contact and non-contact atomic force microscopy (AFM);

- AFM lithography;

- scanning tunneling microscopy (STM);

- AFM and STM microscopy;

- magnetic force microscopy (MFM);

- electric power microscopy (EPM).

SOLVER NEXT scanning probe microscope to investigate surfaces of various materials.

- contact and non-contact atomic force microscopy (AFM);

- AFM lithography;

- scanning tunneling microscopy (STM);

- AFM and STM microscopy;

- magnetic force microscopy (MFM);

- electric power microscopy (EPM).

SOLVER NEXT scanning probe microscope to investigate surfaces of various materials.

Abrasive Diamond-tipped Tools Laboratory

At this laboratory, students pursuing bachelor’s, master’s and graduate programs conduct research in the manufacture and use of bonded diamond-tipped abrasive tools, including ones with thermal conductive bonding, for chemical and mechanical grinding and polishing of a broad range of materials (glass, quartz, sapphire, sitalls, ceramics, silicon carbide, semiconductor materials, metals and alloys).

Automatic and semi-automatic grinding and polishing machines.

Automatic thermal press for manufacturing of bonded abrasive tool specimens.

Automatic and semi-automatic grinding and polishing machines.

Automatic thermal press for manufacturing of bonded abrasive tool specimens.

Specialized Research Laboratory of Chemistry and Physics of Polymers and Polymeric Materials

At this laboratory, students explore the chemical and physical properties of polymers and polymeric materials, acquire skills at producing polymer compositions with technological equipment and assessing the properties of materials with modern testing apparatus.

The equipment available can be used to produce polymer compositions and to study their technological properties (using capillary and rotary rheometers, viscometers, and torque-test mixing equipment), vulcanization properties (using rotor and rotorless vibration rheometers), and physical and mechanical properties (using domestic- or foreign-made tensile testing machines to assess resistance to wear, cyclic loads, and thermal aging).

The structure and morphology of polymers and polymeric composites is researched by means of IR and UV spectrometry, scanning and transmission electron microscopy, and optical microscopy. When measuring surface and interfacial tension in polymers and their mixtures a goniometer is used.

The equipment available can be used to produce polymer compositions and to study their technological properties (using capillary and rotary rheometers, viscometers, and torque-test mixing equipment), vulcanization properties (using rotor and rotorless vibration rheometers), and physical and mechanical properties (using domestic- or foreign-made tensile testing machines to assess resistance to wear, cyclic loads, and thermal aging).

The structure and morphology of polymers and polymeric composites is researched by means of IR and UV spectrometry, scanning and transmission electron microscopy, and optical microscopy. When measuring surface and interfacial tension in polymers and their mixtures a goniometer is used.

Specialized Laboratory of Materials Science and Functional Materials and Structures Engineering

At this laboratory, students explore the fundamental physical and physico-chemical properties of semiconductor materials, master the techniques of semiconductor monocrystal growing using the Czochralski method, epitaxial film growing by liquid-phase epitaxy, deep cleaning of semiconductor materials by zone melting, vacuum metal film sputtering, and photolithographic structure formation; they learn to characterize materials of any dimensions in various states (crystalline, nanocrystalline, amorphous, or gel).

Special Materials and Operational Reliability Laboratory

At this laboratory, students explore the structure and properties of metals and alloys, learn to create materials with given properties, master technical condition assessment methods, including non-destructive testing, and techniques to predict the performance of materials employed various industries, such as aircraft, medicine, engineering, etc.

Mechanical Materials Testing Laboratory

The laboratory is equipped to test the strength and plasticity of metals and alloys by tension, compression, torsion, bending, creep, and fatigue.

The laboratory equipment makes it possible to conduct mechanical testing of materials for tensile resistance, compression, bending, upsetting, flattening, residual deformation, peeling, delamination, shear, and tear in the 0.000005–50 kN range of measurable loads at normal and elevated temperatures up to +1200°C, and to test various materials and specimens for torsion/twisting. The testing machines are geared with a microprocessor-controlled system to control and record the force and strain testing parameters.

The laboratory equipment makes it possible to conduct mechanical testing of materials for tensile resistance, compression, bending, upsetting, flattening, residual deformation, peeling, delamination, shear, and tear in the 0.000005–50 kN range of measurable loads at normal and elevated temperatures up to +1200°C, and to test various materials and specimens for torsion/twisting. The testing machines are geared with a microprocessor-controlled system to control and record the force and strain testing parameters.

Non-Destructive Testing Laboratory

The laboratory makes it possible to study various materials using non-destructive testing and quality examination methods.

Eddy current test devices can help detect surface and subsurface cracks and corrosion, and measure crack depth in products made of magnetic and non-magnetic steels, non-ferrous, refractory metals and alloys. These operations are essential to such industries as nuclear energy, thermal energy, mechanical engineering, metallurgy, the oil, gas and chemical industry, the aircraft industry, railroads and subways.

Ultrasonic flaw detectors make it possible to search, locate and estimate the size of various faults the of continuity or homogeneity of material in metal and plastic products.

The A1550 Introvisor Tomograph is a multi-purpose device to resolve most flaw detection issues, such as weld examination without transverse scanning, detection of faults in materialcontinuity and homogeneity in large-volume metal and plastics products. The device assures visualization of the examined object’s internal structure and makes examination highly efficient.

Magnetic-particle flaw detectors use the magnetic particle method to inspect components and units made of ferromagnetic materials in aircraft, automobile, railroad and other types of equipment.

Eddy current test devices can help detect surface and subsurface cracks and corrosion, and measure crack depth in products made of magnetic and non-magnetic steels, non-ferrous, refractory metals and alloys. These operations are essential to such industries as nuclear energy, thermal energy, mechanical engineering, metallurgy, the oil, gas and chemical industry, the aircraft industry, railroads and subways.

Ultrasonic flaw detectors make it possible to search, locate and estimate the size of various faults the of continuity or homogeneity of material in metal and plastic products.

The A1550 Introvisor Tomograph is a multi-purpose device to resolve most flaw detection issues, such as weld examination without transverse scanning, detection of faults in materialcontinuity and homogeneity in large-volume metal and plastics products. The device assures visualization of the examined object’s internal structure and makes examination highly efficient.

Magnetic-particle flaw detectors use the magnetic particle method to inspect components and units made of ferromagnetic materials in aircraft, automobile, railroad and other types of equipment.

Electrochemical Material Inspection Laboratory

The laboratory is equipped for inspecting the properties of materials using electrochemical techniques. The following types of inspection are available:

- Accelerated corrosion testing with the electrochemical impedance method.

- Corrosion resistance testing with the potentiometric method.

- Corrosion rate assessment of metals, alloys, and coatings, and overall evaluation of the effectiveness of protective measures.

- Evaluation of the protective properties of anodic, chromate and other conversion coatings.

- Intercrystalline corrosion rate estimation.

- Establishment of the granulometric composition of powder materials.

- Measurement of objects’ linear dimensions.

- Establishment of the structural constituents’ ratios.

- Accelerated corrosion testing with the electrochemical impedance method.

- Corrosion resistance testing with the potentiometric method.

- Corrosion rate assessment of metals, alloys, and coatings, and overall evaluation of the effectiveness of protective measures.

- Evaluation of the protective properties of anodic, chromate and other conversion coatings.

- Intercrystalline corrosion rate estimation.

- Establishment of the granulometric composition of powder materials.

- Measurement of objects’ linear dimensions.

- Establishment of the structural constituents’ ratios.

Laboratory on Optical Methods of Material Structure Analysis

The laboratory is equipped for inspecting the structure of various materials (metals, alloys, ceramics, composites) by means of optical analysis. The laboratory equipment makes the following studies possible:

- Determining the volume fraction of constituents and non-metallic inclusions.

- Quantitative grain size estimation using the linear intercept method and area estimation with distribution histograms built.

- Granulometric composition analysis of powder materials with up to x2000 magnification.

- Establishment of the linear dimensions of objects with up to x2000 magnification.

- Determination of the structural constituents’ ratios.

- Inspection of fracture surfaces with up to x2000 magnification and 3D imaging.

- Determining the volume fraction of constituents and non-metallic inclusions.

- Quantitative grain size estimation using the linear intercept method and area estimation with distribution histograms built.

- Granulometric composition analysis of powder materials with up to x2000 magnification.

- Establishment of the linear dimensions of objects with up to x2000 magnification.

- Determination of the structural constituents’ ratios.

- Inspection of fracture surfaces with up to x2000 magnification and 3D imaging.

Computer-Aided Design Department’s Training Laboratory of Firing and Ornamental Casting

At this laboratory, students are trained to work with materials: glass, ceramics, enamels, and epoxy resins. They acquire practical skills with decorative processing techniques: sliding casting, fusing, molding, and enameling.

Computer-Aided Design Department’s Training Laboratory of Research and Experimental Design

At the laboratory, students learn the basics of 3D modeling software and material modeling techniques based on additive and subtractive methods.

Training and Research Center on Magnetoelectric Materials and Devices

The Center is engaged in fundamental and applied research and training of top-level specialists (students pursuing Specialist’s, Master’s, Candidate of Sciences and Doctor of Sciences programs) in micro- and nanoelectronics and microsystem technology, including the following main areas:

- Development of new multiferroid materials (composites, multilayer structures, and thin films) with ferromagnetic, ferroelectric and magnetoelectric properties;

- Analysis of magnetoelectric, magnetic, dielectric, ultrahigh-frequency and temperature characteristics of materials and structures;

- Development of techniques and installations to measure the magnetoelectric, magnetic, dielectric and temperature characteristics of materials and devices in electronics and microsystem engineering;

- Development of new micro- and nanoelectronic devices, microsystem technology, and measuring instruments based on magnetoelectric materials.

At the center, undergraduate and graduate students:

- study magnetoelectric interaction in ferromagnetic-ferroelectric film structures and their uses in creating miniature-size magnetic field sensors and autonomous sources of electrical power;

- explore the properties of materials and the functionalities of electronic devices using unique installations;

- explore magnetic field converters based on magnetoelectric effects in ferromagnetic-piezoelectric composite structures, and such like;

- explore the properties of materials and electronic devices using unique installations.

- Development of new multiferroid materials (composites, multilayer structures, and thin films) with ferromagnetic, ferroelectric and magnetoelectric properties;

- Analysis of magnetoelectric, magnetic, dielectric, ultrahigh-frequency and temperature characteristics of materials and structures;

- Development of techniques and installations to measure the magnetoelectric, magnetic, dielectric and temperature characteristics of materials and devices in electronics and microsystem engineering;

- Development of new micro- and nanoelectronic devices, microsystem technology, and measuring instruments based on magnetoelectric materials.

At the center, undergraduate and graduate students:

- study magnetoelectric interaction in ferromagnetic-ferroelectric film structures and their uses in creating miniature-size magnetic field sensors and autonomous sources of electrical power;

- explore the properties of materials and the functionalities of electronic devices using unique installations;

- explore magnetic field converters based on magnetoelectric effects in ferromagnetic-piezoelectric composite structures, and such like;

- explore the properties of materials and electronic devices using unique installations.

Unique Equipment

The Institute of Physics and Technology has unique scientific equipment installed, including:

Russian-made semi-industrial single-crystal growing installation URN-2-ZP

The unit is used to grow single crystals by fusion-free zone melting of refractory compounds (with a melting point of up to 3000°С) with local optical heating. It is used for research and lab works which are part of the course “The Physical and Chemical Fundamentals of Electronic Technology Materials and Processes.”

Czochralski method-based single-crystal growing machine EKZ-2500 made by Leybold-Heraeus

The machine grows single crystals by the Czochralski method in an inert atmosphere. It is used for basic research by students pursuing Bachelor’s and Master’s programs.

Q-1500 D Derivatograph

The unit is intended for thermogravimetric analysis within the 20–1500°С temperature range in various atmospheres, and for determining the phase transition temperatures and kinetics of chemical transformations. It is used for research and lab work as part of the course “The Physical and Chemical Fundamentals of Electronic Technology Materials and Processes.”

Photoconductivity Study Equipment Set

The set helps to study the photoconductivity of materials in the visible, IR and UV ranges, and to measure the switching rate in pulse modulation modes. It is used for research by undergraduates.

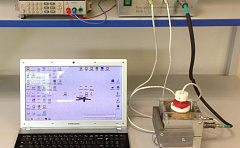

Magnetoelectric Effect Study Equipment Set

The set is intended for undergraduate and graduate students to explore characteristics of the magnetoelectric effect produced by various materials. It is used for research and laboratory work as part of the course “Active Dielectrics.”

Automated Unit to Investigate Temperature Characteristics of Microelectronic Materials, Devices and Microsystems

The automated unit to investigate the temperature characteristics of microelectronic materials, devices and microsystems was developed by RTU MIREA and is designed for prompt measurements of electrical and magnetic parameters of such materials and technology in the –130°C to +130°C temperature range. The unit permits changing the temperature according to a desired law and to display graphs of temperature-value dependencies. It can operate in the automatic or manual mode.

Automated Magnetostriction Measurement Unit

The automated magnetostriction measurement unit was developed by RTU MIREA and permits to promptly measure the magnetostriction-related parameters of magnetic materials used in electronics and microsystems in the 15°C to 80°C temperature range and in magnetic fields up to 1.7 kOe. The unit can also measure angular dependences in magnetostriction.

Automated Magnetoelectric Materials Research Unit

The automated magnetoelectric materials research unit was developed by RTU MIREA and is designed to study the characteristics of single-phase and composite magnetoelectric (ME) material specimens. The unit can measure the frequency, field and amplitude characteristics of specimens when excited by an alternating magnetic or alternating electric field.

- Educational Activity

-

Institutes

- Institute of Information Technologies

-

Institute of Artificial Intelligence

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

- Bachelor's Degree Programs

-

Master's Degree Programs

- 01.04.02 Applied mathematics and information science

- 09.04.01. Informatics and computer engineering

- 12.04.04 Biotechnical systems and technologies

- 15.04.04 Automation of technological processes and production

- 15.04.06 Mechatronics and robotics

- 27.04.03 System analysis and management

- 27.04.04 Engineering system control

- Infrastructure

- Alumni

- Contacts

- Institute for Cybersecurity and Digital Technologies

-

Institute for Advanced Technologies and Industrial Programming

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

-

Bachelor's Degree Programs

- 09.03.02 Information systems and technologies

- 11.03.04 Electronics and nanoelectronics

- 12.03.05 Laser technology and laser techniques

- 15.03.01 Mechanical engineering

- 22.03.01 Materials science and technology

- 27.03.01 Standardization and metrology

- 28.03.01 Nanotechnology and microsystems engineering

- 29.03.04 Decorative material working techniques

- 54.03.01 Graphic design

-

Master's Degree Programs

- 09.04.02. Information systems and technologies

- 11.04.04 Electronics and nanoelectronics

- 12.04.02 Optical engineering

- 15.04.01 Mechanical engineering

- 22.04.01 Materials science and technology

- 27.04.01 Standardization and metrology

- 29.04.04 Decorative material working techniques

- 54.04.01 Graphic design

-

Bachelor's Degree Programs

- Infrastructure

- Alumni

- Contacts

- Institute of Radio Electronics and Informatics

- Institute of Management Technologies

- Lomonosov Institute of Fine Chemical Technologies

- Institute of International Education

-

Mega-Laboratories

- Motion Capture Laboratory

- Immersive Technologies Laboratory

- Laboratory for the Development and Transfer of Microfluidic Technologies (DTMT)

- Cell Technologies Megalaboratory operating on the basis of the Department of Chemistry and Technology of Biologically Active Compounds, Medical and Organic Chemistry named after N.A. Preobrazhensky

- General Biotechnology Megalaboratory

- Industry 4.0: Digital Robotized Production center

- Laboratory of Intelligent Autonomous and Multi-Agent Robotic Systems

- Research and Educational Center for Biosynthesis, Isolation and Purification of Monoclonal Antibodies (Generium)

- Rare and Precious Metals Research and Technological Center operating on the basis of the Department of Chemistry and Technology of Rare Elements named after K.A. Bolshakov

- Laboratory of Analytic, Modeling, Design and Digital Prototyping Technologies

- Import Substitution of Information Technologies Educational and scientific testing complex

- Smart Production Systems Educational and Scientific Center

- Elastomers. Thermoplastics. Technologies Educational and Research Center operating on the basis of the Department of Chemistry and Technology of Elastomer Processing named after F.F. Koshelev

- Catalytic and Mass Exchange Processes center

- Center of Innovative Technologies in Microelectronics

- Centre for Additive Polymer Technologies

- Center for Cybersports Robotics

- Mobile Robotics University Laboratory

- Radio electronic Technologies Megalaboratory

- Situation center

- Scientific and Educational Center for Medical Radiology and Dosimetry

- Laboratory of Geographic Information Systems and Technologies

- Educational and Research Center for Space Monitoring ("CosMoCenter")

- Techno-coworking

- Bachelor's Degree Programs

- Master's Degree Programs

- Additional Education Programs

- Physical Education and Sports

© 2025 MIREA - Russian Technological University