15.03.01 Mechanical engineering

Students pursuing this area of studies receive instruction in modern machine parts manufacturing processes, including additive manufacturing processes in mechanical engineering, and learn to design CAD-models of parts of any complexity and to plan their manufacturing processes using modern digital technologies.

Level of education:

Bachelor’s degree

Form of training:

Full-time (daytime)

Venue of training:

Moscow

Entrance exams:

— Mathematics (major)

— Russian language

— Physics/Information science and ICT

— Russian language

— Physics/Information science and ICT

Programs, specializations:

Digital and additive technologies in mechanical engineering

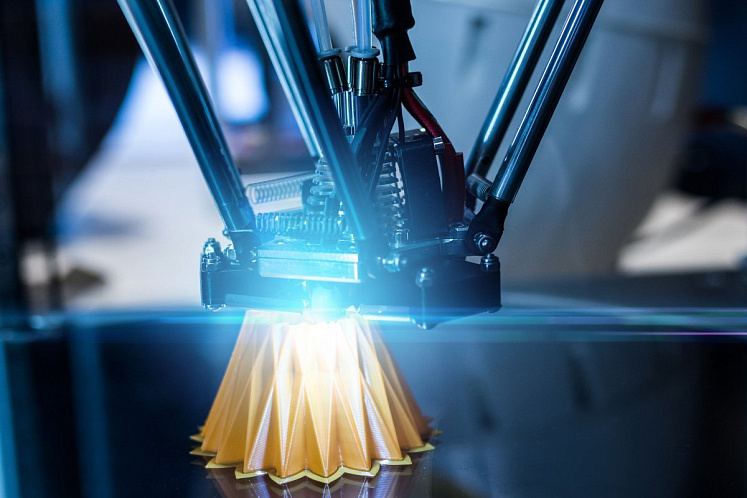

The program is focused on current machine manufacturing processes, including additive processes as the most dynamically developing and promising techniques associated with the building of digital three-dimensional models, production planning and maintenance involving 3D printers and other installations for additive manufacture.

Students will be able to research and design processes for additive manufacture of products out of polymers and metallic materials using computer (digital) 3D models of any complexity, to incorporate additive techniques in the manufacturing of engineering products, to design component manufacturing processes with the use of relevant software and computer-aided design systems, and to implement such processes by operating and programming modern CNC hardware.

Completion of the program enables the student to solve current issues of machine manufacture process support, to perform comparative analyses of different processes and to choose the optimal one; to conduct research in the field of additive and mechanical production processes in mechanical engineering, and to control product quality at all stages of the production process.

Students will be able to research and design processes for additive manufacture of products out of polymers and metallic materials using computer (digital) 3D models of any complexity, to incorporate additive techniques in the manufacturing of engineering products, to design component manufacturing processes with the use of relevant software and computer-aided design systems, and to implement such processes by operating and programming modern CNC hardware.

Completion of the program enables the student to solve current issues of machine manufacture process support, to perform comparative analyses of different processes and to choose the optimal one; to conduct research in the field of additive and mechanical production processes in mechanical engineering, and to control product quality at all stages of the production process.

Alumni can be employed as

- manufacturing engineer

- researcher

- research engineer

Program subjects

- Mechanical and additive manufacture technologies

- Digital model development for additive manufacturing

- 3D printing materials and technologies in mechanical engineering

- Real-object digitization techniques and tools

- Equipment and tooling of mechanical and additive manufacturing

- Product control methods in additive manufacturing

- Assurance of production process accuracy

- Programming of numerically controlled equipment

- Automated production process design systems

Digital and Additive Technologies Department

- Educational Activity

-

Institutes

- Institute of Information Technologies

-

Institute of Artificial Intelligence

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

- Bachelor's Degree Programs

-

Master's Degree Programs

- 01.04.02 Applied mathematics and information science

- 09.04.01. Informatics and computer engineering

- 12.04.04 Biotechnical systems and technologies

- 15.04.04 Automation of technological processes and production

- 15.04.06 Mechatronics and robotics

- 27.04.03 System analysis and management

- 27.04.04 Engineering system control

- Infrastructure

- Alumni

- Contacts

- Institute for Cybersecurity and Digital Technologies

-

Institute for Advanced Technologies and Industrial Programming

- About the Institute

- Institute Administration

- History of the Institute

-

Training programs

-

Bachelor's Degree Programs

- 09.03.02 Information systems and technologies

- 11.03.04 Electronics and nanoelectronics

- 12.03.05 Laser technology and laser techniques

- 15.03.01 Mechanical engineering

- 22.03.01 Materials science and technology

- 27.03.01 Standardization and metrology

- 28.03.01 Nanotechnology and microsystems engineering

- 29.03.04 Decorative material working techniques

- 54.03.01 Graphic design

-

Master's Degree Programs

- 09.04.02. Information systems and technologies

- 11.04.04 Electronics and nanoelectronics

- 12.04.02 Optical engineering

- 15.04.01 Mechanical engineering

- 22.04.01 Materials science and technology

- 27.04.01 Standardization and metrology

- 29.04.04 Decorative material working techniques

- 54.04.01 Graphic design

-

Bachelor's Degree Programs

- Infrastructure

- Alumni

- Contacts

- Institute of Radio Electronics and Informatics

- Institute of Management Technologies

- Lomonosov Institute of Fine Chemical Technologies

- Institute of International Education

-

Mega-Laboratories

- Motion Capture Laboratory

- Immersive Technologies Laboratory

- Laboratory for the Development and Transfer of Microfluidic Technologies (DTMT)

- Cell Technologies Megalaboratory operating on the basis of the Department of Chemistry and Technology of Biologically Active Compounds, Medical and Organic Chemistry named after N.A. Preobrazhensky

- General Biotechnology Megalaboratory

- Industry 4.0: Digital Robotized Production center

- Laboratory of Intelligent Autonomous and Multi-Agent Robotic Systems

- Research and Educational Center for Biosynthesis, Isolation and Purification of Monoclonal Antibodies (Generium)

- Rare and Precious Metals Research and Technological Center operating on the basis of the Department of Chemistry and Technology of Rare Elements named after K.A. Bolshakov

- Laboratory of Analytic, Modeling, Design and Digital Prototyping Technologies

- Import Substitution of Information Technologies Educational and scientific testing complex

- Smart Production Systems Educational and Scientific Center

- Elastomers. Thermoplastics. Technologies Educational and Research Center operating on the basis of the Department of Chemistry and Technology of Elastomer Processing named after F.F. Koshelev

- Catalytic and Mass Exchange Processes center

- Center of Innovative Technologies in Microelectronics

- Center for Cybersports Robotics

- Mobile Robotics University Laboratory

- Radio electronic Technologies Megalaboratory

- Departmental Situation Center of the Ministry of Science and Higher Education of the Russian Federation for monitoring the sphere of education and science

- Scientific and Educational Center for Medical Radiology and Dosimetry

- Laboratory of Geographic Information Systems and Technologies

- Educational and Research Center for Space Monitoring ("CosMoCenter")

- Additive Polymer Technologies Center

- Cyber Threat Research Megalaboratory

- Digital Center of Rosatom State Corporation

- Laser Technologies Megalaboratory

- Mathematical Modeling and Artificial Intelligence Megalaboratory

- Megalaboratory of Digital and Additive Technologies in Mechanical Engineering

- Nanomaterials and Nanostructures Diagnostics Center

- Techno-coworking

- TESLA Educational and Research Center

- Bachelor's Degree Programs

- Master's Degree Programs

- Additional Education Programs

- Physical Education and Sports

© 2026 MIREA - Russian Technological University